Tape

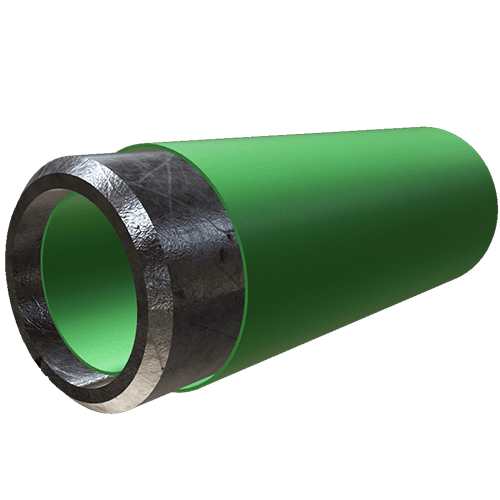

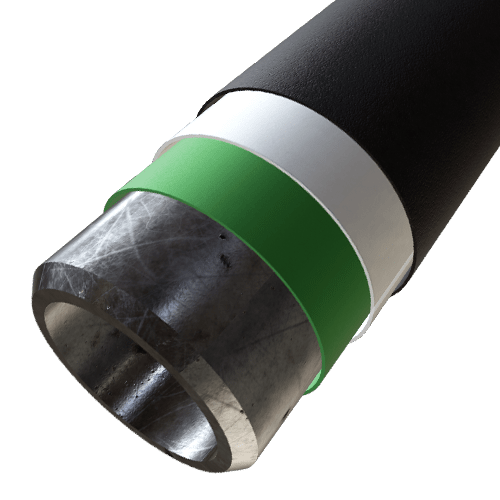

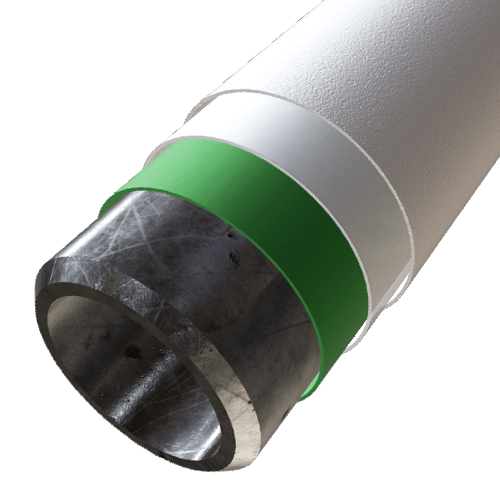

EXTERNAL COATING

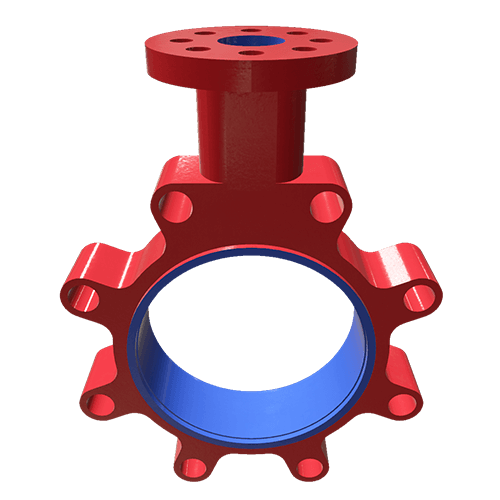

V.I.P. Pesaro is one of the few companies able to offer the tape coating on pipes as well fittings, field joints and bends.

The coating can be applied also on a primer fusion bonded epoxy (FBE)

Tape coating is a multilayer primarily constituted by a primer to protect the pipe surface from corrosion damage, the outer layer protects the piece from mechanical stresses.

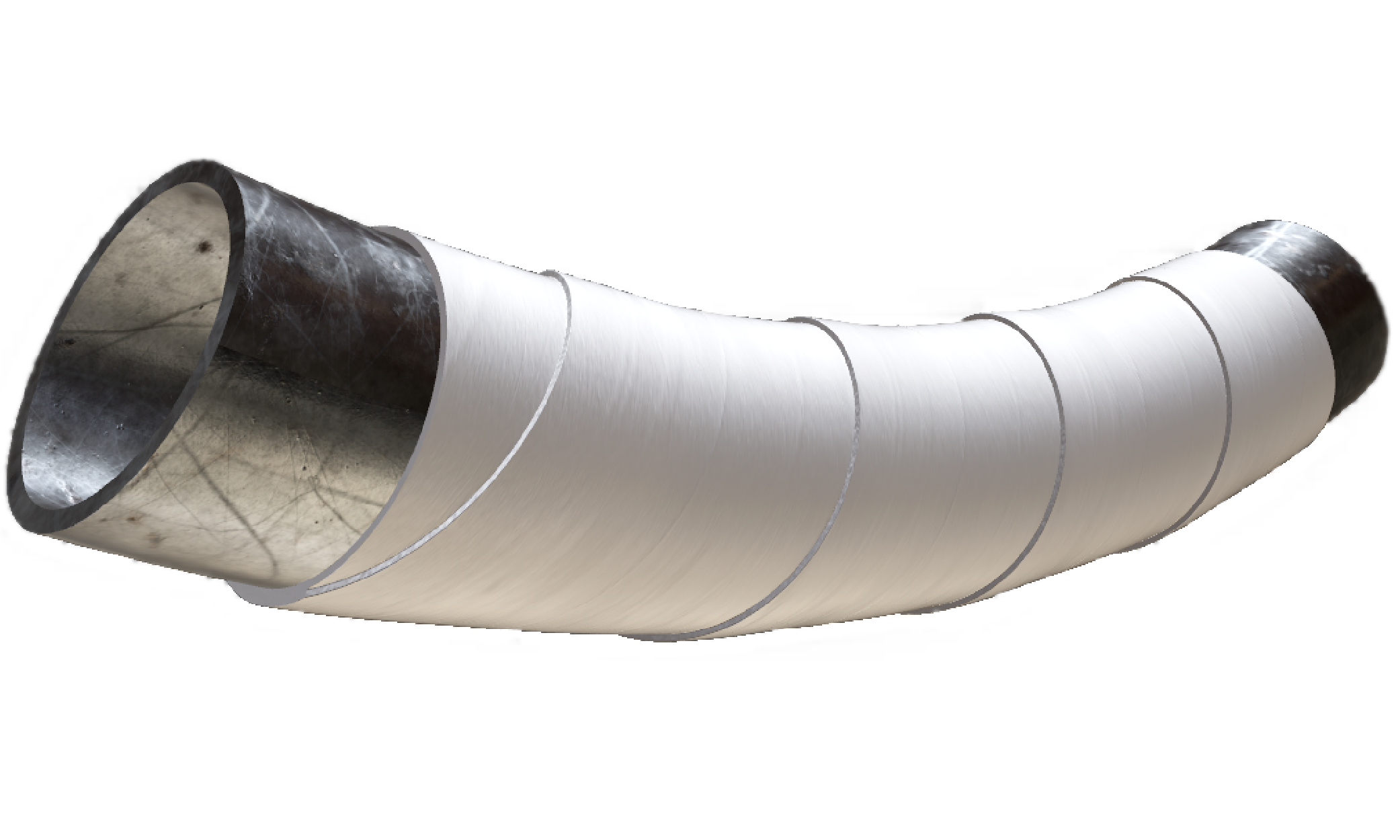

The material applied externally is in the form of tapes (spiral or “cigarette” wrapping).

Primers, adhesives or fillers can be used in conjunction with these coating to improve adherence or facilitate application.

This technique is mainly used for external organic coatings: system of pipes, fittings, valves and joint assemblies, intended for the transport of gaseous, liquid or solid substances; for the corrosion protection of buried or immersed steel pipelines used in conjunction with cathodic protection.

Types of coating materials

• Petrolatum tape (cold applied)

Corrosion protection tape consisting of a synthetic reinforcement coated on both sides with a semi-solid petrolatum compound mouldable at ambient temperature.

• Bituminous tape (hot applied):

Corrosion protection tape consisting of glass or synthetic reinforcement coated on both sides with a bituminous compound.

• Silicone-Epoxy tape (…applied):

anti-corrosive wrapping products for pipes used under a sever condition of high temperature (till 300°C). Its physical properties show non-sticky and very stable anti-corrosion resistance and water-proof for a long period.

Polymeric Tapes

Corrosion protection tapes, hot or cold applied, consisting of a compound highly adhesive to steel and generally bonded to a flexible polymer film and may contain a synthetic reinforcement.

Following some subdivisions:

• Laminate polymeric tape:

Corrosion protection tape consisting of a flexible polymer film, coated on both sides with an adhesive compound. This compound could be reinforced with synthetic fibers.

• Reinforced polymeric tape:

Corrosion protection tape consisting of a synthetic reinforcement, coated on both sides with an adhesive compound and containing an additional polymer film.

• Low strength polymeric tape:

Corrosion protection tape consisting only of an adhesive compound. It may contain a flexible polymer film to avoid overstretching during application.

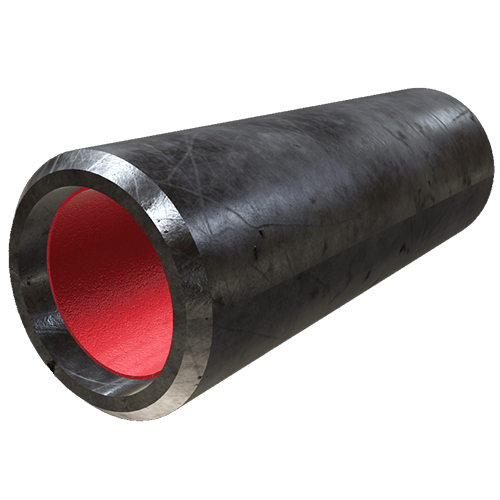

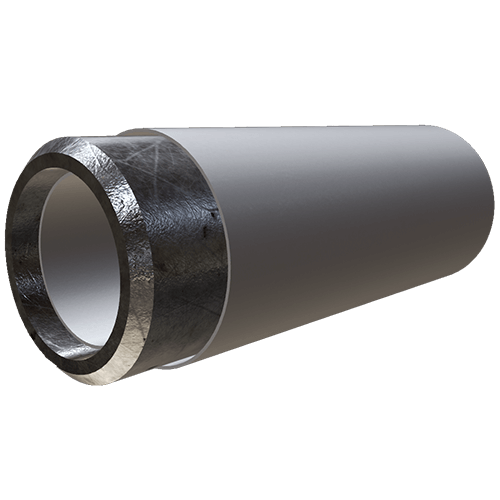

- Small and large pipes

- Standard and special fittings

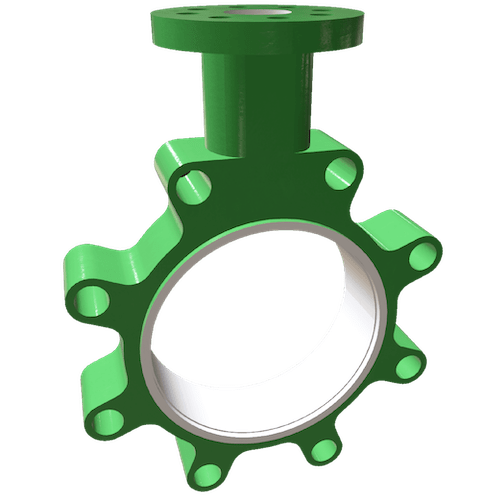

- Flanges

- Field joints

– impact resistance

– indentation resistance

– specific electrical insulation resistance

– cathodic disbondment resistance

– peel strength layer to layer

– peel strength to pipe surface and coating

– thermal ageing resistance

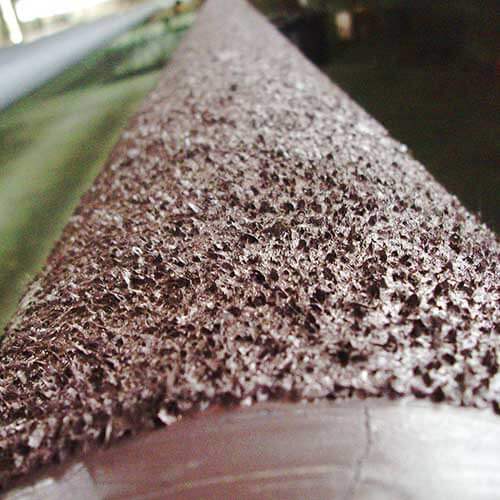

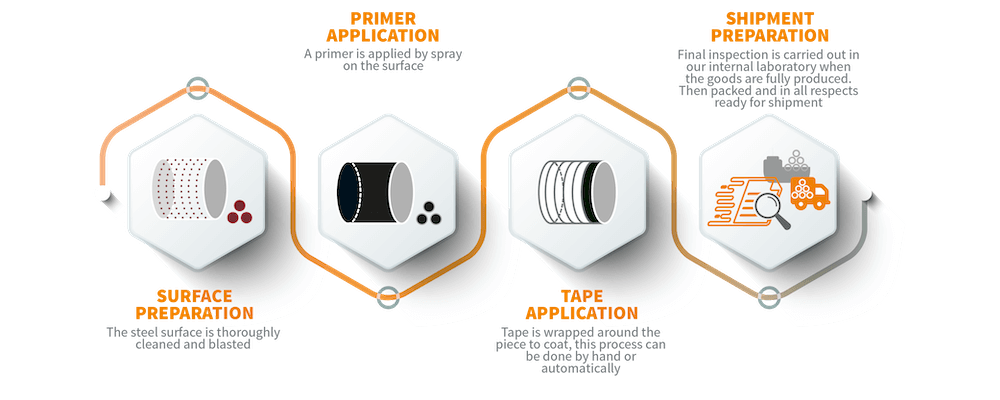

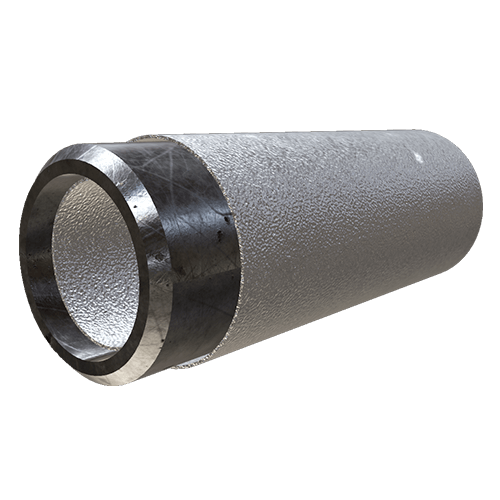

- SURFACE PREPARATION : The steel surface is thoroughly cleaned and blasted.

- PRIMER APPLICATION : A primer is applied by spray on the surface.

- TAPE APPLICATION : Tape is wrapped around the piece to coat, this process can be done by hand or automatically.

- SHIPMENT PREPARATION : Final inspection is carried out in our internal laboratory when the goods are fully produced, packed and in all respects ready for shipment.

WRAPPING PROCESS

EXTERNAL COATING

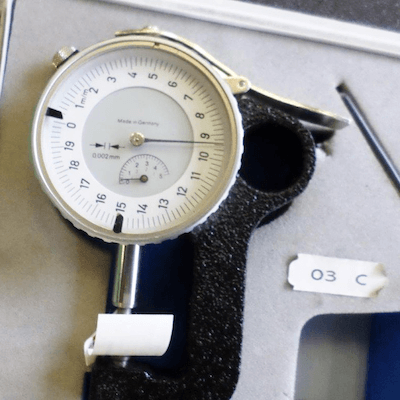

INSPECTION AND TESTING

These are merely approximate values adjustable according to clients’ requirements.

| Property | Test Description | Typical Values |

|---|---|---|

| Operating temperature | EN 12068:1998 | from -20°C till 300°C |

| Insulating resistance | DIN 30672 | 10^17 MΩm^2 |

| Adhesion strength | DIN 30672 | >120 Kgf/cm^2 |

| Cathodic disbondment resistance | EN 12068:1998 | at 23°C: ≤ 20 mm |

| Indentation resistance pressure | EN 12068:1998 | at 23°C: from 0.1 to 10 N/mm^2 |

COATING CAPACITY

Pipes:

Diameter from 1/2” to 120”

Maximum unit length 13.5 meters

Maximum unit weight 15,000 kg.

Joints and/or custom pieces: (bends, tees, reducers, flanges, etc.)

Maximum size 3.0 x 3.0 x 13.5 meters

Maximum unit weight 15,000 kg

Maximum thickness of the coating 3,5 mm