Polyurethane without solvents

PU w/o solvents

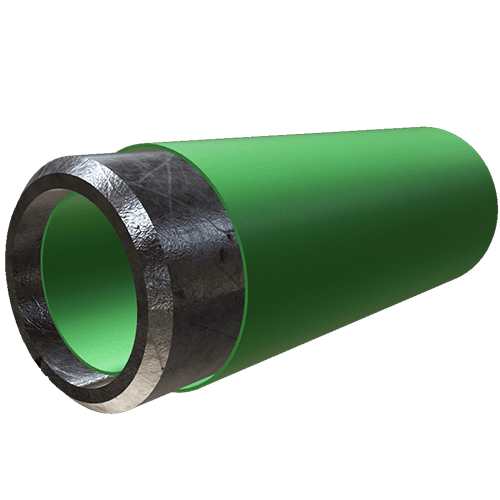

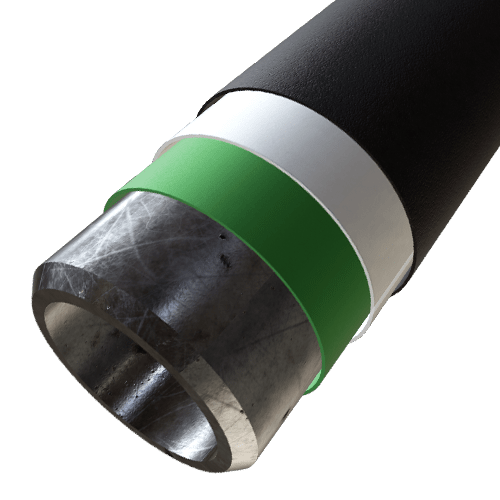

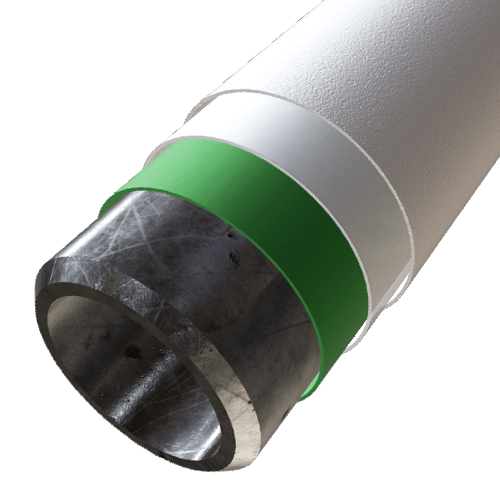

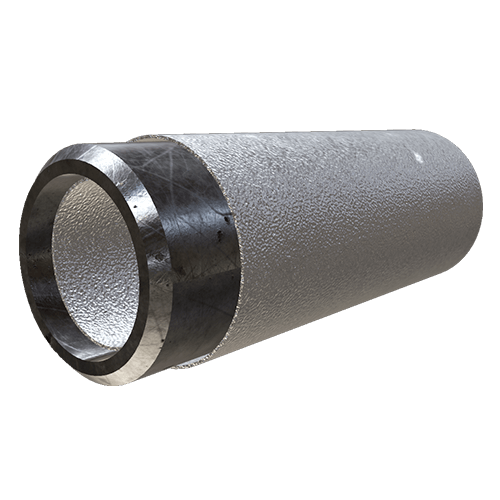

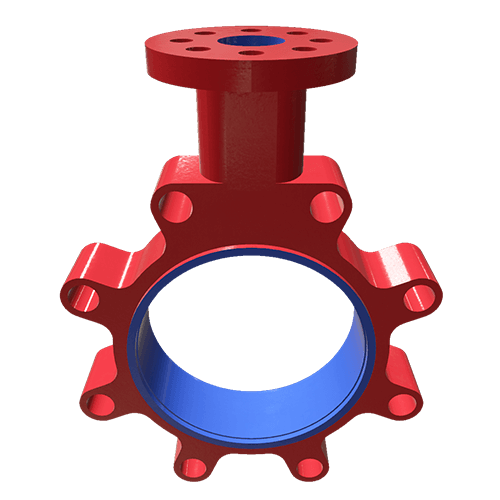

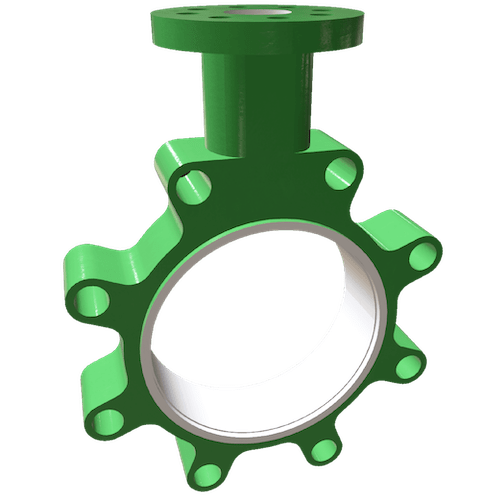

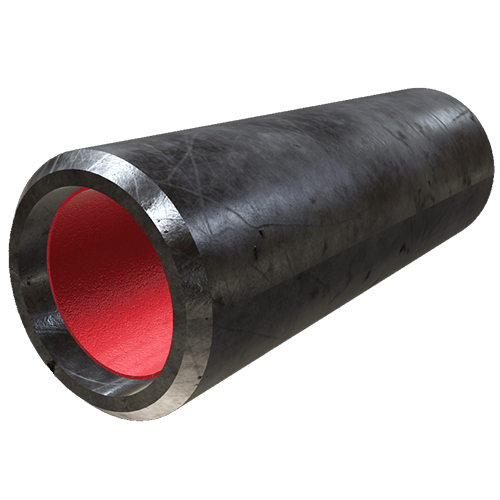

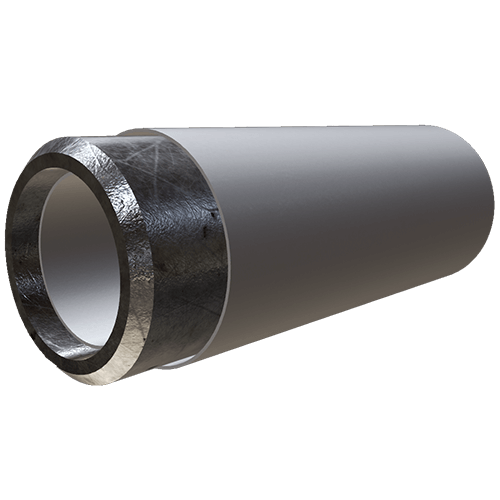

EXTERNAL COATING AND INTERNAL LINING

This is a fast-drying polyurethane bi-component with low environmental impact as it does not contain solvents, bitumen or tar.

It provides steel surfaces valuable and long-lasting protection against corrosion, thanks to its barrier action. It can only be applied hot using special high pressure airless equipment.

It has an extremely low permeability to water and good resistance to cathode detachment.

Long-term anticorrosive protection

Polyurethane without solvents can be used for protecting products which work in both low and high temperatures, it has good properties of chemical resistance even in aggressive industrial environments, supports unforeseeable variations in underground humidity and has good resistance to attack from microorganisms in the soil or marine environment.

Very good mechanical protection

Guarantees very good mechanic resistance to abrasion and blows during installation, thanks to its characteristic flexibility.

Other advantages of PU coating

As it can also be applied with a brush using a special version of the product, it is possible to guarantee the continuity of the coating even onto very complex items. There are no limits in the quantity of pieces which may be coated, even individual pieces may be treated. Differentiated thicknesses can be applied in order to meet the specific design specifications.

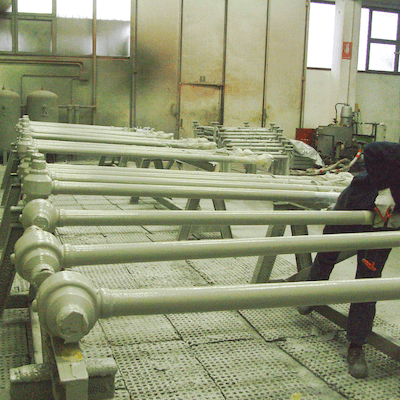

- Small and large pipes

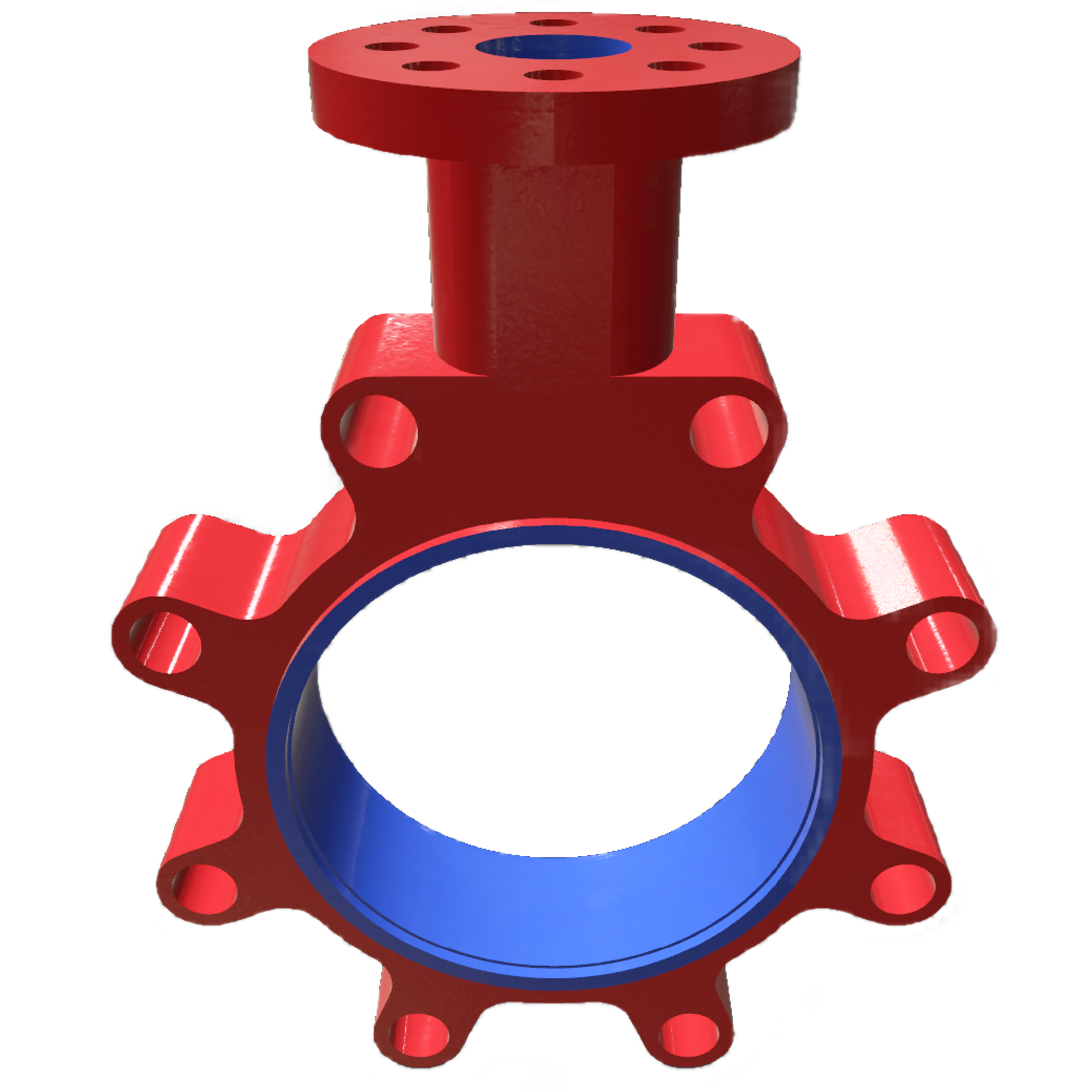

- Standard and special fittings

- Wide radius bends

- Flanges

- Custom pieces

- Buckle arrestors

- Field joints

- Tank

- Waterworks components

- Steel structures

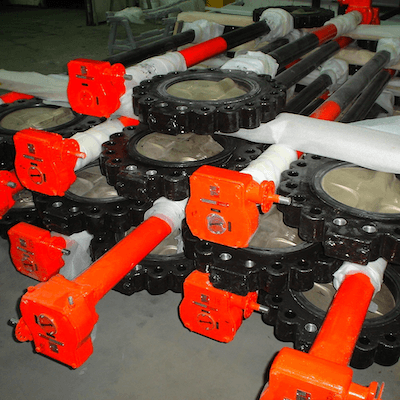

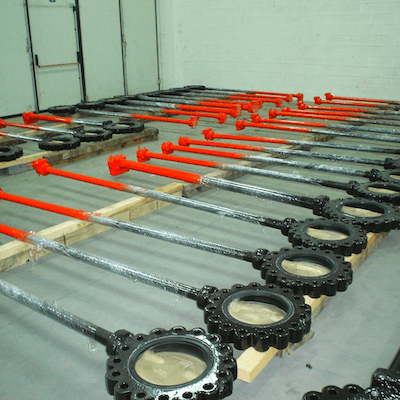

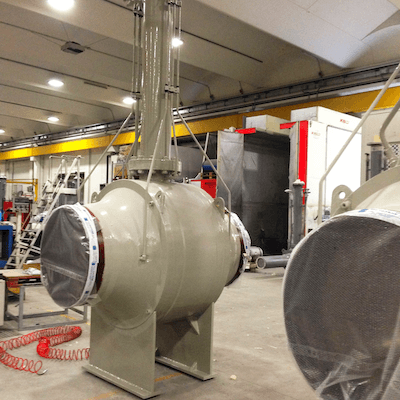

- Valves

Hardness : 75 shore D; 62 shore D 2h at 80°C

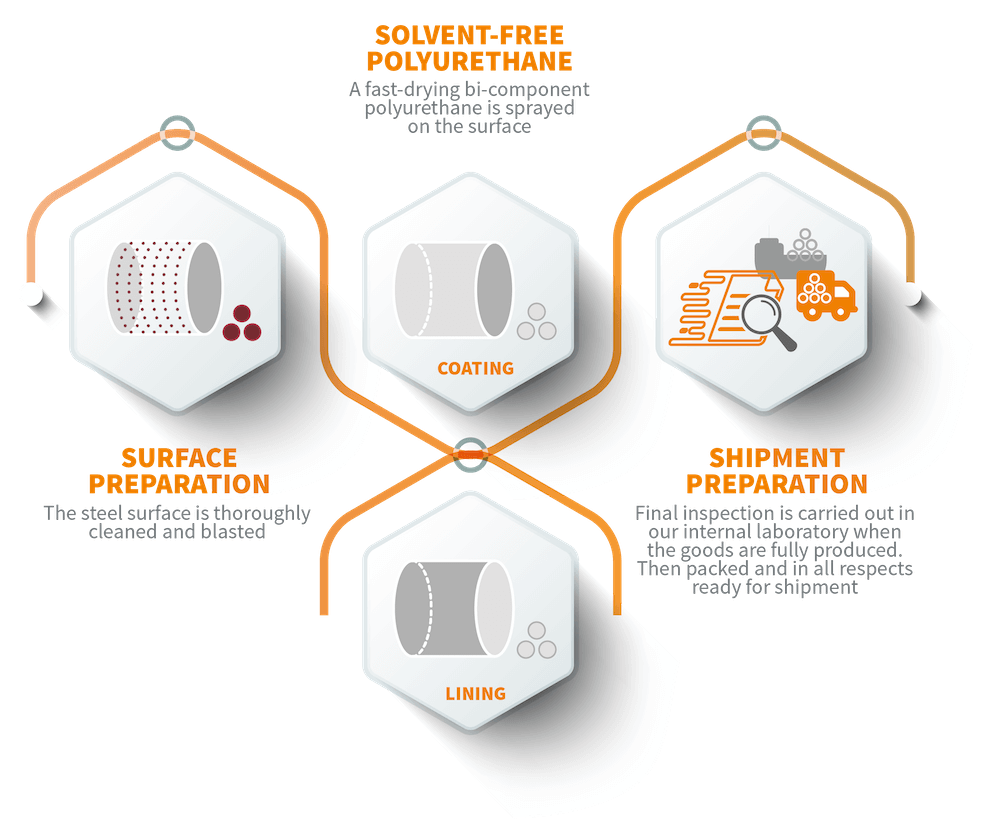

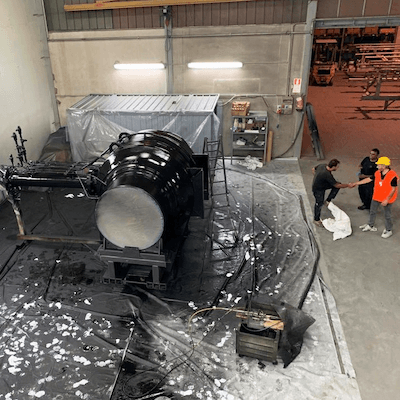

- SURFACE PREPARATION : The steel surface is thoroughly cleaned and blasted.

- SOLVENT-FREE POLYURETHANE : A fast-drying bi-component polyurethane is sprayed on the surface.

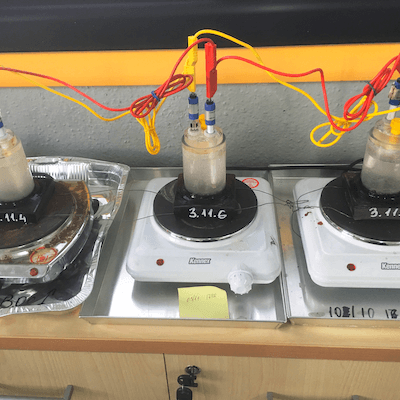

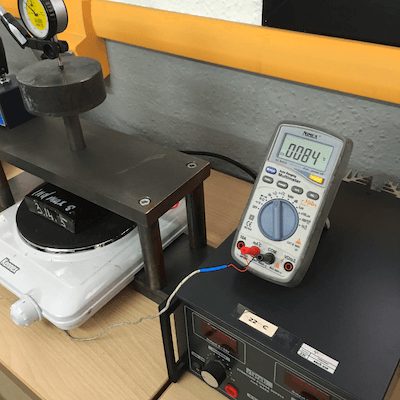

- SHIPMENT PREPARATION : Final inspection is carried out in our internal laboratory when the goods are fully produced. Then packed and in all respects ready for shipment.

PU W/O SOLVENTS PROCESS

EXTERNAL COATING

INTERNAL LINING

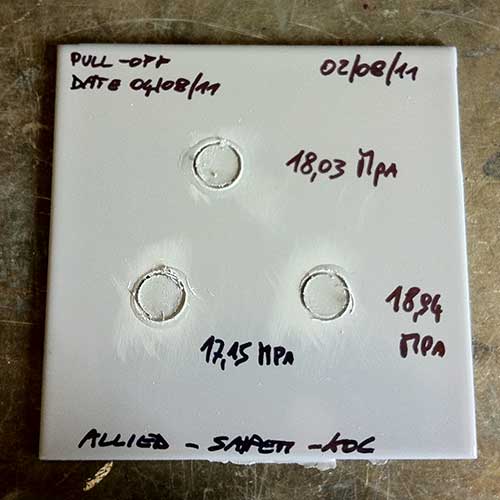

INSPECTION AND TESTING

These are merely approximate values adjustable according to clients’ requirements.

| Property | Test Description | Typical Values |

|---|---|---|

| Specific electrical insulation | DIN EN 10290 | after 100dy at 23 °C – (1.8)*10^9Ωm2 |

| Impact | DIN EN 10290 | Test voltage = 20 kV at 23 °C Impact (max.) = 10 J Test voltage = 18 kV at 23 °C Impact = 8 J/mm |

| Cathodic Disbonment | DIN EN 10290 | 28dy at 23 °C – 2,8mm; 28dy at 90 °C – 13mm |

| Pull-off | DIN EN 10290 | at 23 °C: 8 MPa; at 90°C: 6MPa |

| Thermal aging (adhesion test) | DIN EN 10290 | after 100dy at 100 °C : 13 MPa |

COATING CAPACITY

Pipes:

Diameter from 1/2” to 120”

Maximum unit length 13.5 meters

Maximum unit weight 15,000 kg.

Joints and/or custom pieces: (bends, tees, reducers, flanges, etc.)

Maximum size 3.0 x 3.0 x 13.5 meters

Maximum unit weight 15,000 kg

Maximum thickness of the coating 3,5 mm