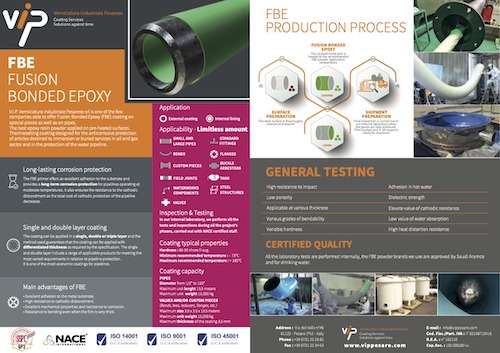

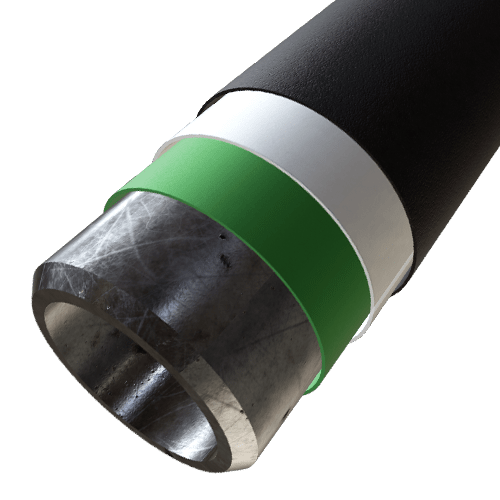

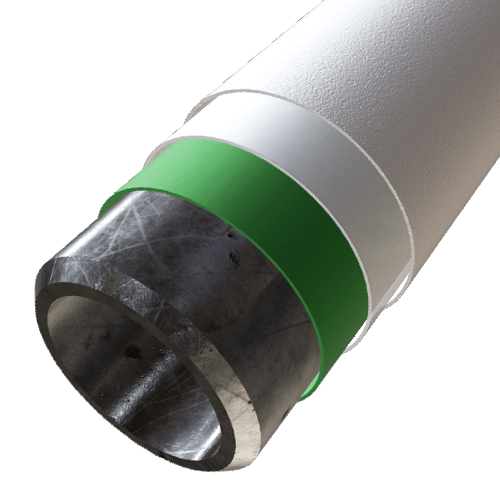

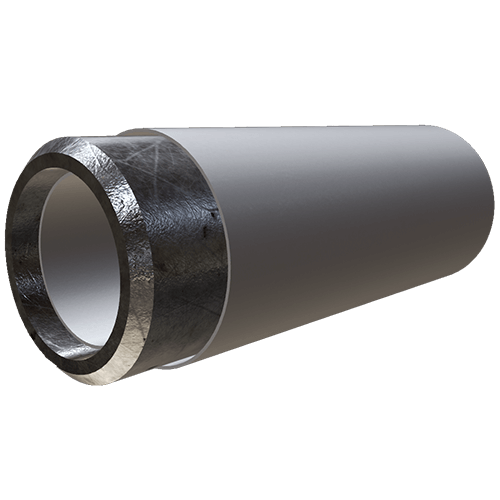

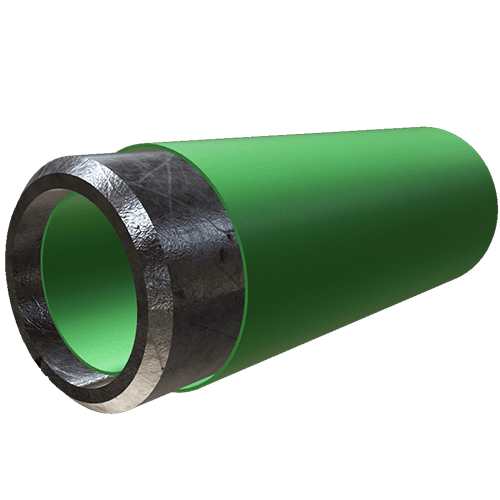

Dual-layer Fusion Bonded Epoxy – (ARO)

Abrasion Resistant Overcoat

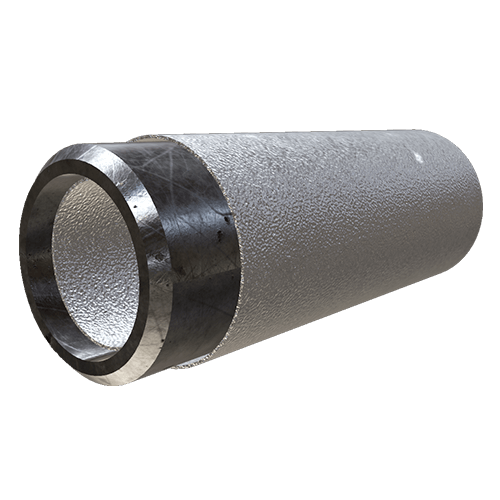

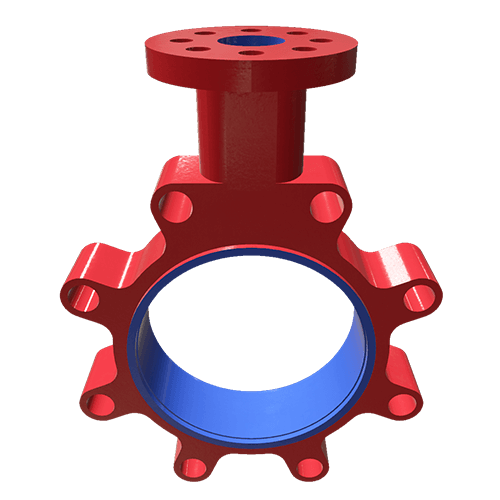

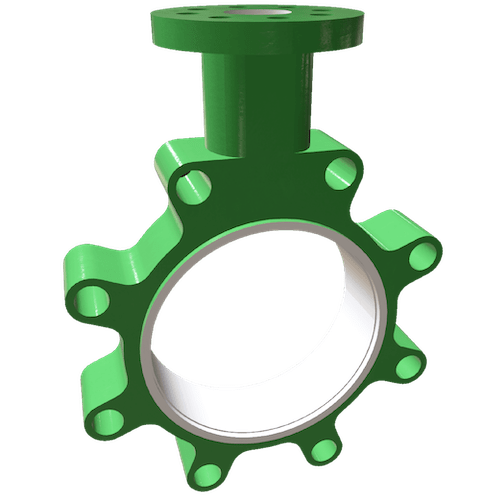

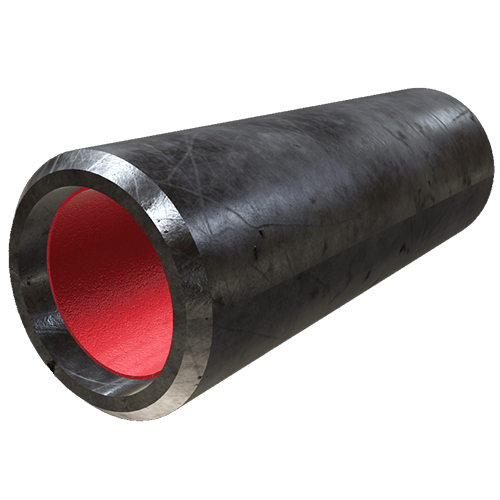

EXTERNAL COATING AND INTERNAL LINING

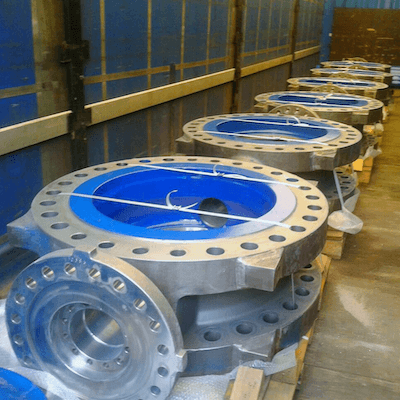

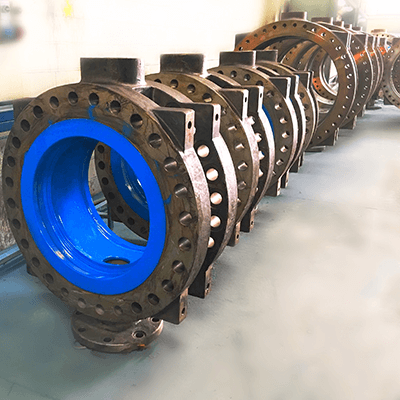

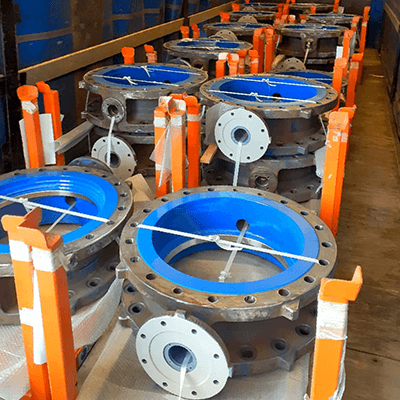

V.I.P. Verniciatura Industriale Pesarese srl is one of the few companies able to offer Dual-layer Fusion Bonded Epoxy (ARO – Abrasion Resistant Overcoat) coating on special pieces as well as on pipes.

The dual-layer provides mechanical-damage resistance from gouging or impact during handling and construction.

The best epoxy resin powder applied on pre‐heated surfaces.

Thermosetting coating designed for the anticorrosive protection of articles destined to immersion or buried services in oil and gas sector and in the protection of the water pipeline.

The coating can be applied in a single (FBE – Fusion Bonded Epoxy), double or triple layer and the method used guarantees that the coating can be applied with differentiated thickness as required by the specification.

Main advantages:

– Excellent adhesion to the metal substrate.

– High resistance to cathode detachment.

– Anti slip

– Ultraviolet (UV) resistant

– Excellent resistance to corrosion and mechanical properties, especially during construction.

– Resistant to bending even when the film is very thick.

Long-lasting corrosion protection

The FBE primer offers an excellent adhesion to the substrate and provides a long-term corrosion protection for pipelines operating at moderate temperatures.

It also ensures the resistance to the cathodic disbondment so the total cost of cathodic protection of the pipeline decreases.

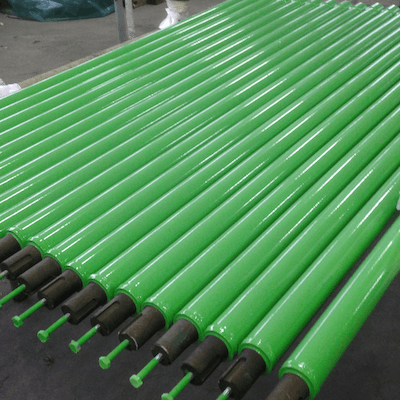

- Small and large pipes

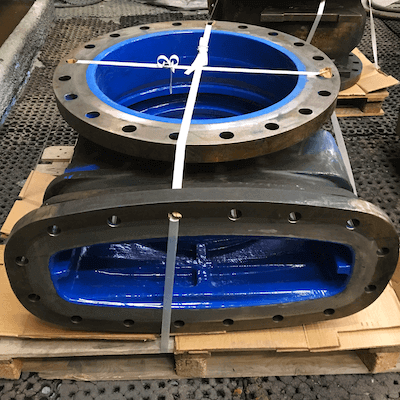

- Standard and special fittings

- Wide radius bends

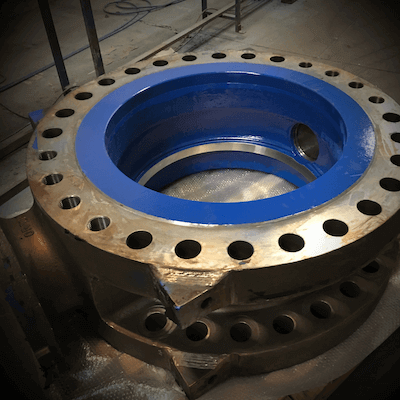

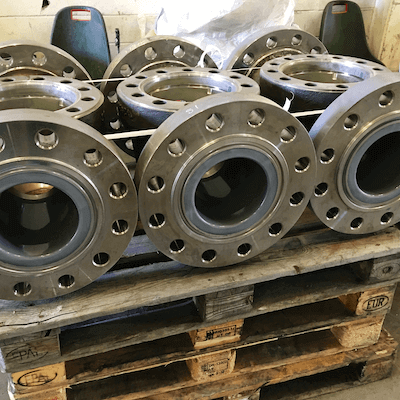

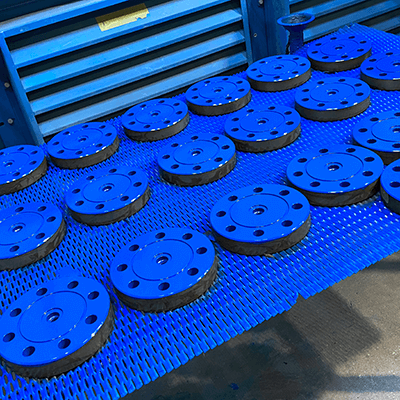

- Flanges

- Custom pieces

- Elongation at Break : > 600%

- Hardness : Shore D 52

- Minimum recommended temperature : – 40°C

- Maximum recommended temperature : + 80°C

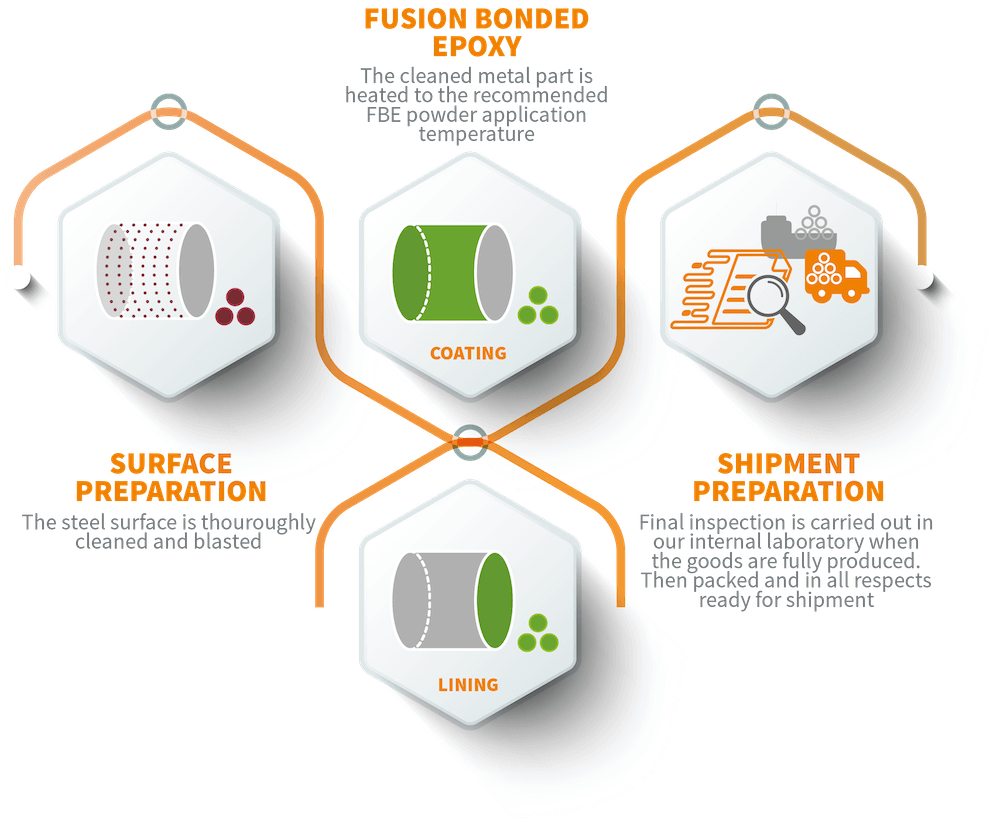

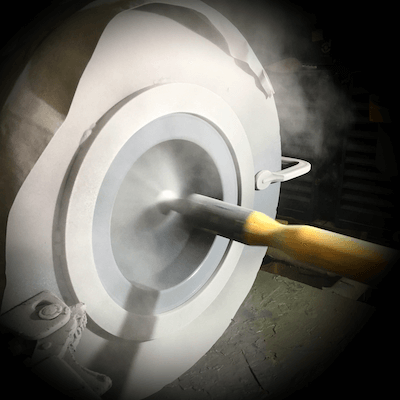

- SURFACE PREPARATION : The steel surface is thoroughly cleaned and blasted.

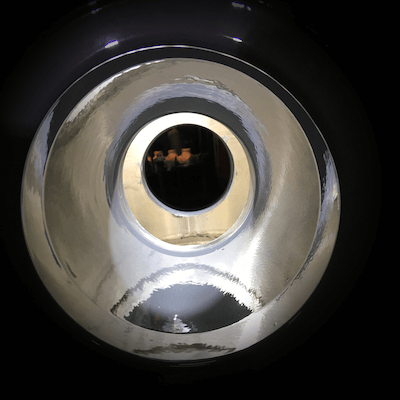

- FUSION BONDED EPOXY – Anticorrosive coating* : The cleaned metal part is heated to the recommended FBE powder application temperature.

- FUSION BONDED EPOXY – Abrasion Resistant Overcoat*

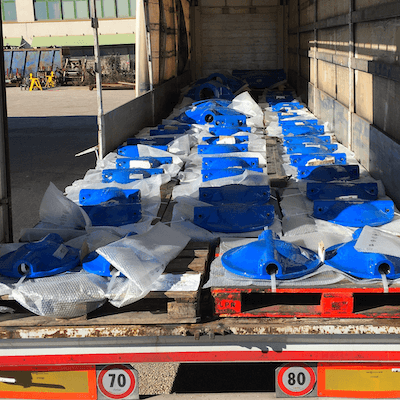

- SHIPMENT PREPARATION : Final inspection is carried out in our internal laboratory when the goods are fully produced. Then packed and in all respects ready for shipment.

*Sintering is the coating process where a coating powder is sprayed on a preheated piece. Thanks to the heat emitted from the surface the powder fuses creating an homogeneous and continuous layer.

Selected from among the top qualified international brands by the biggest companies.

Selected raw materials and internationally recognized with qualifications from certified bodies.

(AWWA ‐ KIWA ‐ DNV etc.)

DUAL-LAYER FBE (ARO) PROCESS

EXTERNAL COATING

INTERNAL LINING

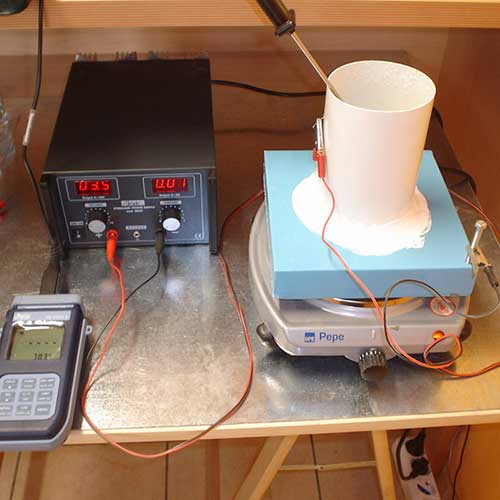

INSPECTION AND TESTING

| Property | Test Description | Typical Values |

|---|---|---|

| Degree of cure of epoxy resin | DIN 30670 | ∆Tg according to the manufacturer specifications |

| Impact | DIN 30670 | ≥ 7 J/mm |

| Cathodic Disbondment | DIN 30670 | 23°C/ 28 days or 60°C/ 2 days max 7 mm |

| Peel Strenght | DIN 30670 | 35 N/cm at 23°C; 15 N/cm at 70°C |

| Continuity (holiday detection) | DIN 30670 | 10 kV/mm; max 25kV |

COATING CAPACITY

Pipes:

Diameter from 1/2” to 120”

Maximum unit length 13.5 meters

Maximum unit weight 15,000 kg.

Joints and/or custom pieces: (bends, tees, reducers, flanges, etc.)

Maximum size 3.0 x 3.0 x 13.5 meters

Maximum unit weight 15,000 kg

Maximum thickness of the coating 3,5 mm

FBE Coating – More application

FBE Coating – More application

V.I.P. Pesaro takes care of customers needs designing custom coatings for special pieces in order to always satisfy clients expectations. Since more than ten years we are providing our protective solutions worldwide.

We offer specific consultancy since the analyses of project requirements. We design the best solution selecting with the client the most suitable coating and the best applicable technique. After realization, we carry out laboratory tests to truly guarantee a perfect results.