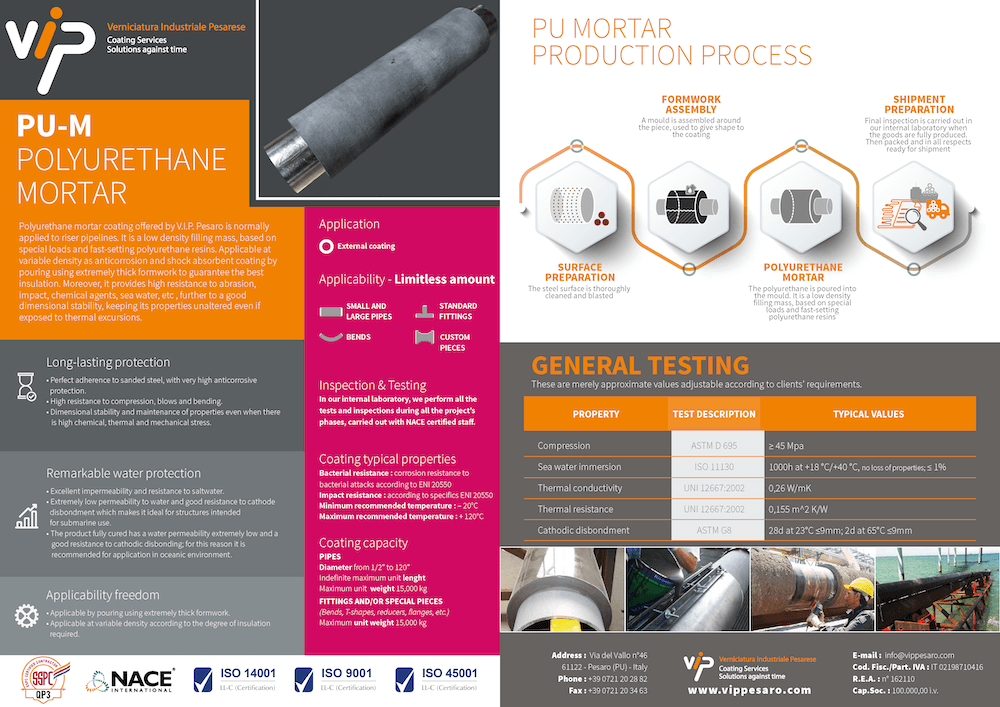

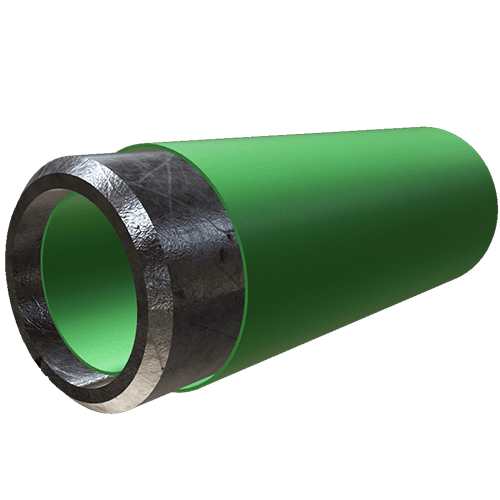

Polyurethane mortar

PU-M mortar

EXTERNAL COATING

Polyurethane mortar coating offered by V.I.P. Pesaro is normally applied to riser pipelines.

It is a low density filling mass, based on special loads and fast-setting polyurethane resins.

Applicable at variable density as anticorrosion and shock absorbent coating by pouring using extremely thick formwork to guarantee the best insulation. Moreover, it provides high resistance to abrasion, impact, chemical agents, sea water, etc , further to a good dimensional stability, keeping its properties unaltered even if exposed to thermal excursions.

Long-lasting protection

• Perfect adherence to sanded steel, with very high anticorrosive protection.

• High resistance to compression, blows and bending.

• Dimensional stability and maintenance of properties even when there is high chemical, thermal and mechanical stress.

Remarkable water protection

• Excellent impermeability and resistance to saltwater.

• Extremely low permeability to water and good resistance to cathode disbondment which makes it ideal for structures intended for submarine use.

• The product fully cured has a water permeability extremely low and a good resistance to cathodic disbonding; for this reason it is recommended for application in oceanic environment.

Applicability freedom

• Applicable by pouring using extremely thick formwork.

• Applicable at variable density according to the degree of insulation required.

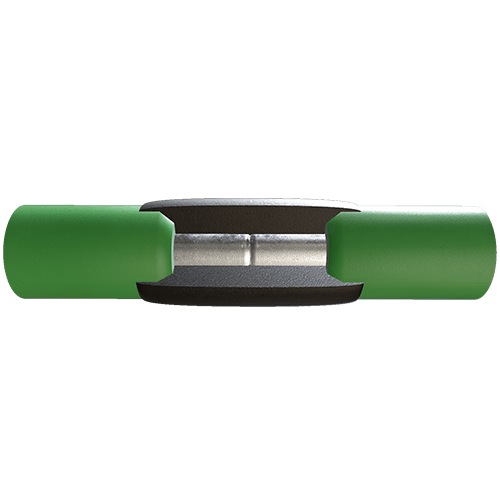

- Small and large pipes

- Standard fittings

- Wide radius bends

- Custom pieces

Impact resistance : according to specifics ENI 20550

Minimum recommended temperature : – 20°C

Maximum recommended temperature : + 120°C

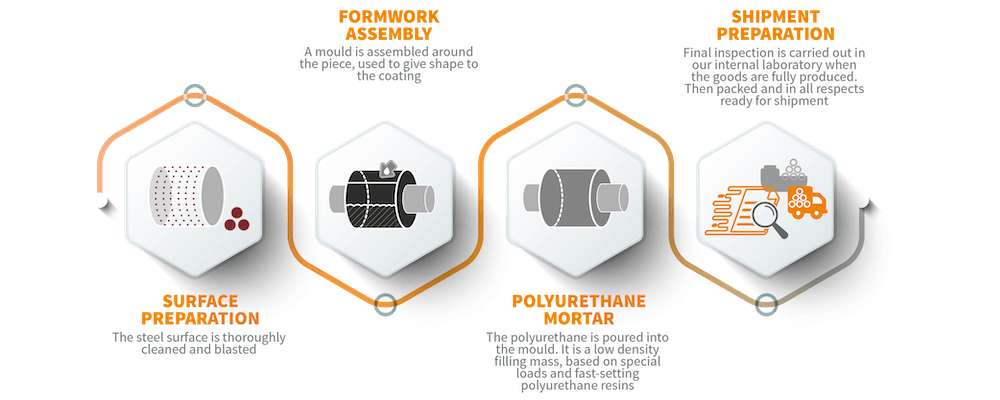

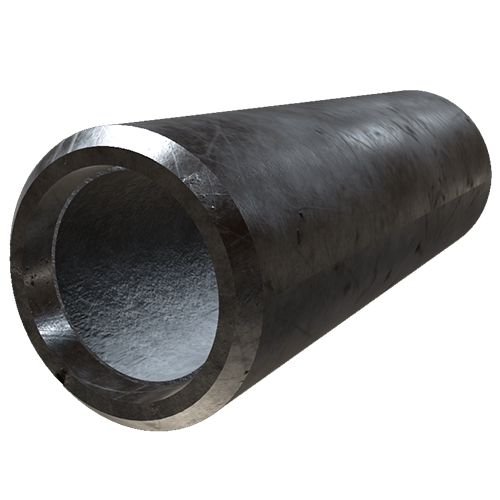

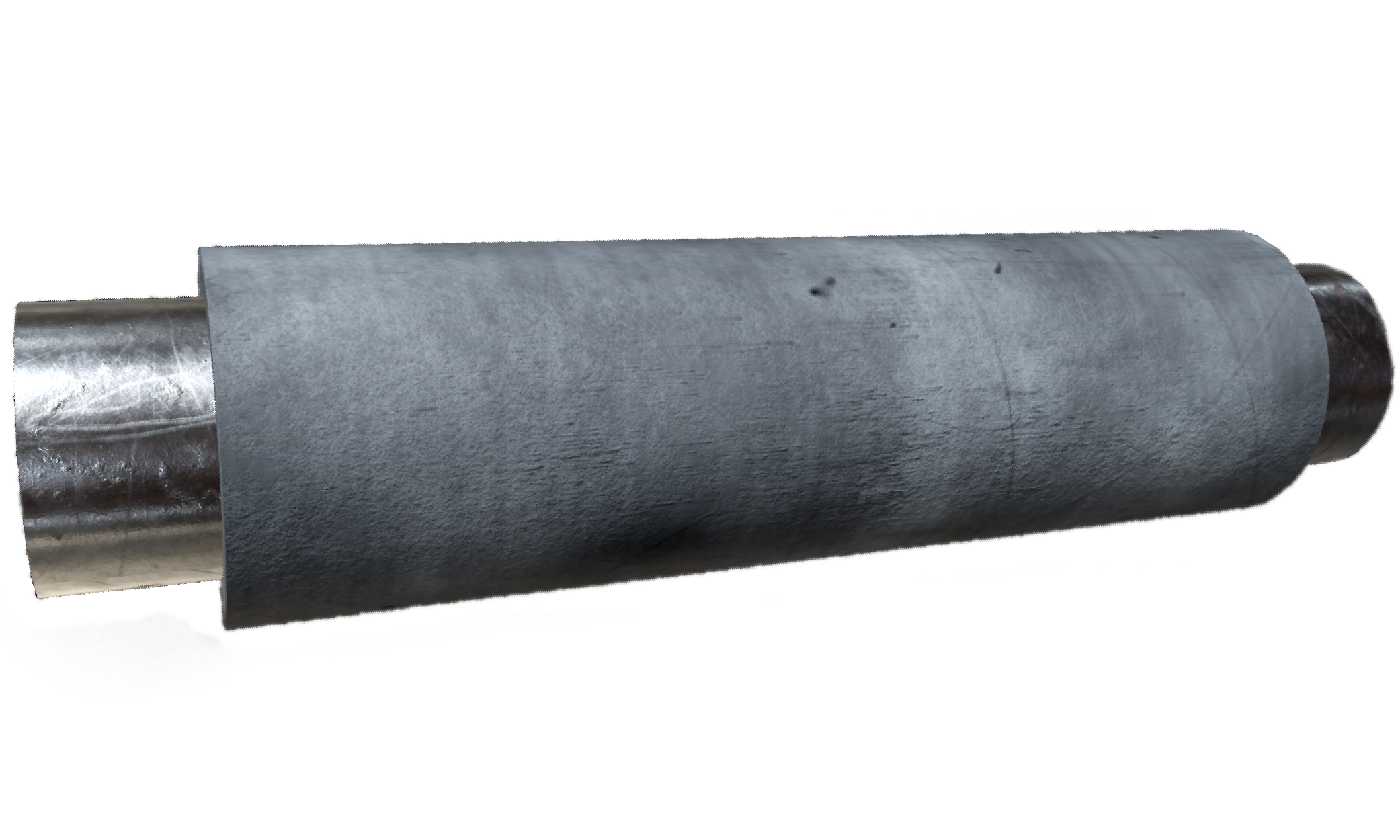

- SURFACE PREPARATION : The steel surface is thoroughly cleaned and blasted.

- FORMWORK ASSEMBLY : A mould is assembled around the piece, used o give shape to the coating.

- POLYURETHANE MORTAR : The polyurethane is poured into the mould. It is a low density filling mass, based on special loads and fast-setting polyurethane resins.

- SHIPMENT PREPARATION : Final inspection is carried out in our internal laboratory when the goods are fully produced, packed and in all respects ready for shipment.

POLYURETHANE MORTAR PROCESS

EXTERNAL COATING

INSPECTION AND TESTING

These are merely approximate values adjustable according to clients’ requirements.

| Property | Test Description | Typical Values |

|---|---|---|

| Compression | ASTM D 695 | ≥ 45 Mpa |

| Sea water immersion | ISO 11130 | 1000h at +18 °C/+40 °C, no loss of properties; ≤ 1% |

| Thermal conductivity | UNI 12667:2002 | 0,26 W/mK |

| Thermal resistance | UNI 12667:2002 | 0,155 m^2 K/W |

| Cathodic disbondment | ASTM G8 | 28d at 23°C ≤9mm; 2d at 65°C ≤9mm |

COATING CAPACITY

Pipes:

Diameter from 1/2” to 120”

Maximum unit length 13.5 meters

Maximum unit weight 15,000 kg.

Joints and/or custom pieces: (bends, tees, reducers, flanges, etc.)

Maximum size 3.0 x 3.0 x 13.5 meters

Maximum unit weight 15,000 kg

Maximum thickness of the coating 3,5 mm