Thermal Spray Coating

TSC Metallizing

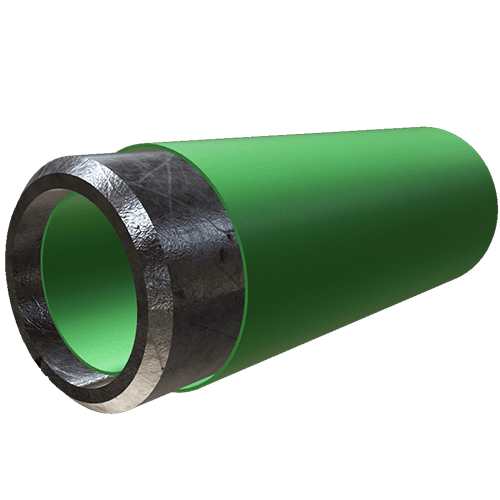

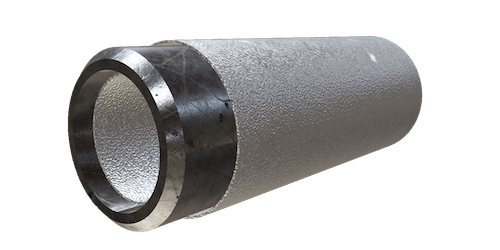

EXTERNAL COATING AND INTERNAL LINING

V.I.P. Pesaro is able to offer electric arc, Thermal Spray Coating.

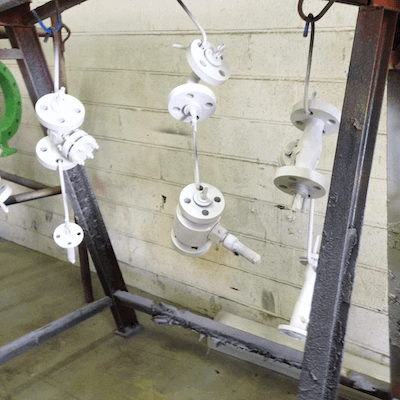

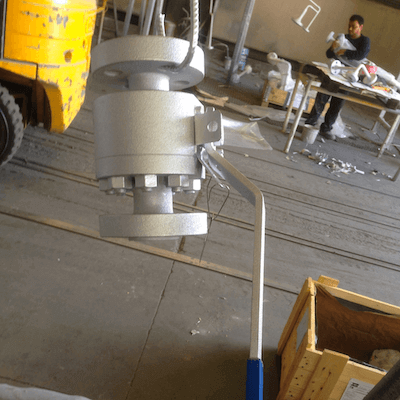

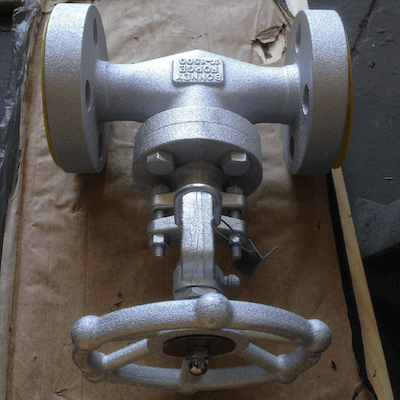

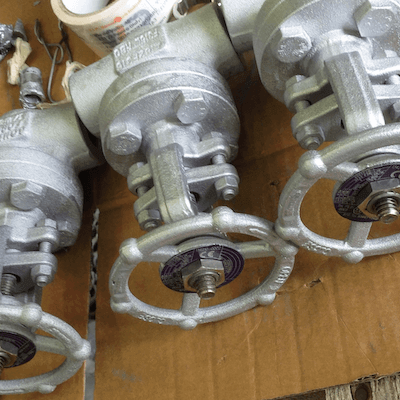

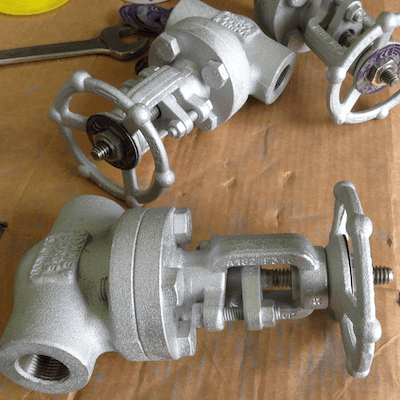

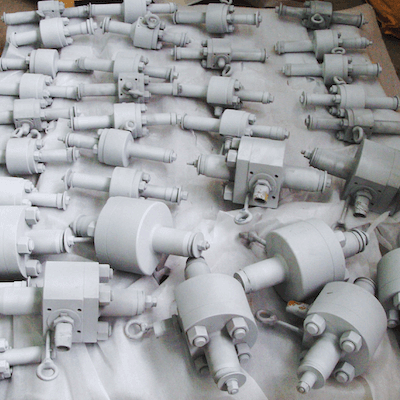

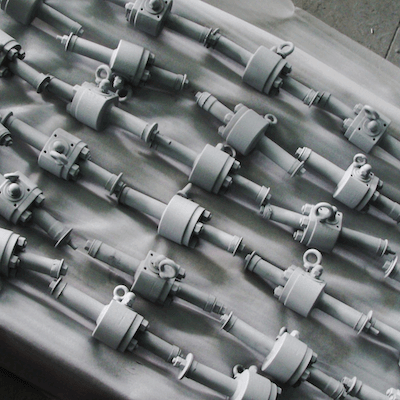

TSC Metallizing can be applied on all components as well pipes as valves (Check our last commission).

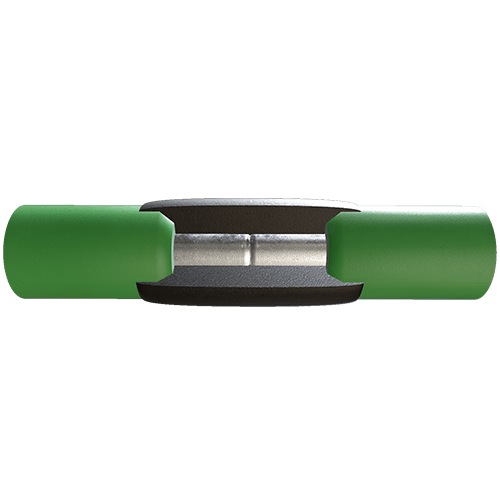

Metal insert can be applied without sealant guaranteeing excellent anticorrosive protection.

Both sealed or painted can be used in any type of environment, thanks to coating characteristics.

Long-lasting protection

• Very flexible process applicable to pieces without limitations in quantity, size and weight.

• Surface heating limitation in order not to alter the characteristics of treated product.

• Can be applied in factory as well on worksite using suitable equipments.

• Ensures higher anticorrosive protection in comparison with any other protective system.

• Possibility of carrying out restorations and/or repairs on hot galvanized surfaces.

• Very long-lasting coating even in highly aggressive environments.

• Flame spray and thermal spray.

Coatings with sealant

Sealed metallization offers a range of long-lasting coatings even in highly aggressive environments. It is normally used for off-shore applications.

Main advantages:

• Excellent mechanical properties.

• High anti-corrosive properties.

• Applicable in various thicknesses using several metals having completely different characteristics.

Coating without sealant

The metal insert without sealant is used to meet a variety of requirements concerning pipeline protection. Coating with zinc wire can be used as an alternative to hot galvanising.

Main advantages:

• Excellent mechanical properties and resistance to corrosion.

• Anticorrosive protection even when damaged.

• High resistance to high temperatures.

• Applicable without size restrictions.

Sealed metallization offers a range of long-lasting coatings even in highly aggressive environments.

It is normally used for off-shore applications.

Main advantages:

- Excellent mechanical properties.

- High anti-corrosive properties.

- Applicable in various thicknesses using several metals having completely different characteristics.

The metal insert without sealant is used to meet a variety of requirements concerning pipeline protection. Coating with zinc wire can be used as an alternative to hot galvanising.

Main advantages:

- Excellent mechanical properties and resistance to corrosion.

- Anticorrosive protection even when damaged.

- High resistance to high temperatures.

- Applicable without size restrictions.

- Small and large pipes

- Standard and special fittings

- Wide radius bends

- Flanges

- Custom pieces

- Buckle arrestors

- Field joints

- Tank

- Waterworks components

- Steel structures

- Valves

TSZn : Zinc 99,995%

TSAl 99.0Cu : Aluminium 99,0% min.

TSAl : Aluminium 99,5% min.

TSZn/Al : 85% Zinc (purity 99,995%) + 15% Aluminium (purezza 99,70%)

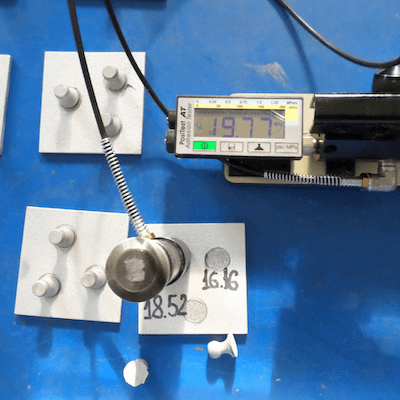

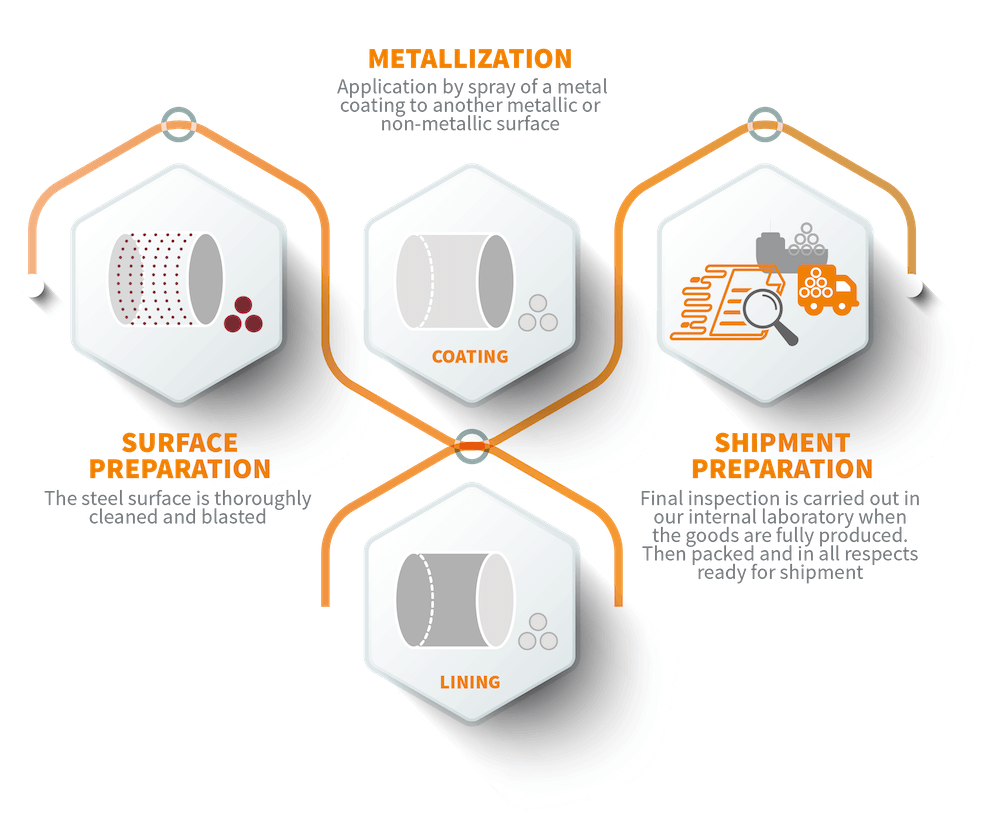

- SURFACE PREPARATION : The steel surface is thoroughly cleaned and blasted.

- THERMAL SPRAY COATING : Electric arc metallization Sealed application if requested.

- SHIPMENT PREPARATION : Final inspection is carried out in our internal laboratory when the goods are fully produced, packed and in all respects ready for shipment.

TSC METALLIZING PROCESS

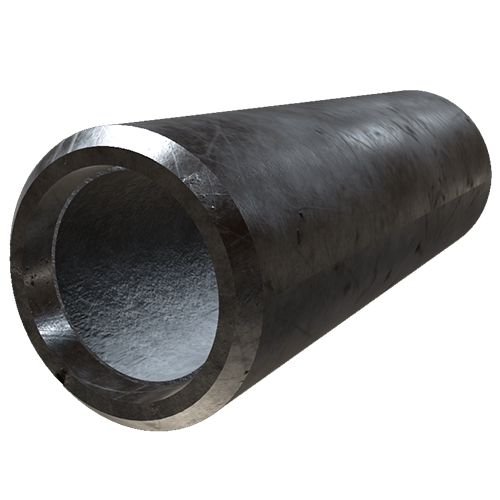

EXTERNAL COATING

INTERNAL LINING

INSPECTION AND TESTING

These are merely approximate values adjustable according to clients’ requirements.

| Property | Test Description | Typical Values |

|---|---|---|

| Adhesion | EN ISO 2063 | TSZn: 4,82 MPa (700 psi); TSAl99:13,78 MPa (2000 psi) |

| EN ISO 2063 | TSAl: 13,78 MPa (2000 psi); TSZn/Al: 8,25 MPa (1205 psi) | |

| Hardness | EN ISO 2063 | TSZn: 143 Knoop 100, 12-15HB; |

| EN ISO 2063 | TSAl99: 55 Knoop 100, 25-30HB; | |

| EN ISO 2063 | TSAl: 55 Knoop 100, 25-30HB; TSZn/Al: 15-20HB |

COATING CAPACITY

Pipes:

Diameter from 1/2” to 120”

Maximum unit length 13.5 meters

Maximum unit weight 15,000 kg.

Joints and/or custom pieces: (bends, tees, reducers, flanges, etc.)

Maximum size 3.0 x 3.0 x 13.5 meters

Maximum unit weight 15,000 kg

Maximum thickness of the coating 3,5 mm